3D printers are very versatile pieces of newly developed equipment. They can be used to print a 3D model for just about anything, which is why they have become indispensable in various industries. Whether it is for personal use, industrial use, or for 3D printing services open to the public, 3D printers can deliver limitless possibilities. However, there are various things that you should keep in mind to ensure that you are choosing the right 3D printer for your needs. These types of printers can be quite costly, therefore, winding up with the wrong 3D printer can be problematic. This is why we are here to tell you useful tips that will help you choose the right 3D printer.

General Tips

Before buying a 3D printer, it helps to keep the following few pointers in mind. Make sure you know exactly what you plan on printing before you set out to get a 3D printer. The gear and industrial production compartments can differ a lot, cost-wise. This is why having an idea of what you are going to print, how frequently you will be printing, when and where the printing objects will be used, and the amount of time that you plan on investing in the printing process, is quite important. You should also determine your preferred printing style. There are four types of 3D printers: Selective Laser Sintering (SLS), Fused Deposition Modeling Printer (FDM), Digital Light Processing (DLP), and Stereolithography (SLA). The printer should come with safety measures, such as nozzles that automatically move away when the machine is paused, to prevent the formation of excess filament and head damage. FDM uses a filament, while DLP and SLA use vats of liquid resin. SLS printers use powder instead of resin.

Make sure that your printer comes with high-quality features, including dual filament support, a touchscreen user interface, and heated glass beds. The resolution of a 3D printer is measured in microns and is something to look out for. FDM machines typically range between 25 and 100 microns, depending on the quality of the printer that you purchase. However, in most cases, the resolution can be easily adjusted, making belt tension and layer height even more important factors to consider to ensure a smooth printing procedure. You should also settle for a brand that offers excellent customer support in case anything goes wrong.

What You Will Be Printing

If you plan on printing items that won’t be exposed to moisture or light, such as household or office equipment, you can consider purchasing 3D printers with filaments made of Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), or Polyethylene Terephthalate Glycol (PETG). If your item has anything to do with food, then you should go for PETG or any other food-safe filament that is coated with food-safe epoxy. For more detail-oriented items, you can opt for resin printers. The 3D printing specialists at Printing Atoms explain that the tools that you will need heavily rely on what and where the item will be utilized. ABS prints on an FDM printer can be necessary with sufficient infill. However, FDM printers may not suffice for professional use. The types of printers that are used among manufacturers in industries such as dentistry, automotive, and aerospace are resin printers.

Printer Style

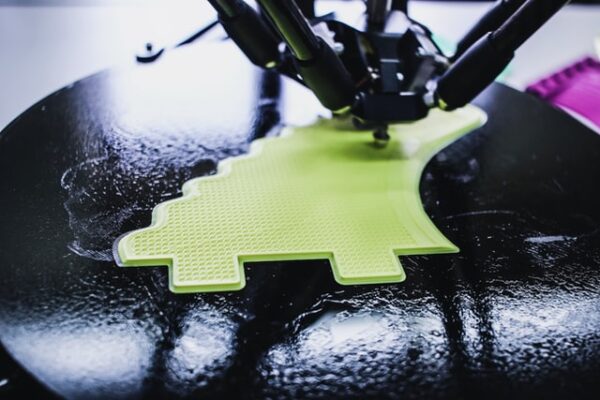

Fused Deposition Modeling Printers operate by heating filaments, feeding them through a tube, and creating the shape along the 3 axes. They are not ideal when it comes to creating horizontal lines, this means that the final product often needs to be smoothed out. A Delta or Cartesian style frame construction can be reconnected. Most printing enthusiasts lean toward Cartesian FDM printers that move the X and Z-axes with their motors while moving the bed along the Y-axis, offering more control and resulting in better end products. A Delta-style construction moves with 3 motors that operate on rods that are evenly spaced. Stereolithography printers use photons to focus on a certain point, resulting in solidified resin. It is a precise process that results in smooth and high-quality products. Each layer of the product is created by vat polymerization in Digital Light Processing. Selective Laser Sintering printers focus a laser on certain points inside the powder’s vat to create new layers.

3D printers are not only used in several industries, but they are also used by average enthusiasts who look forward to creating fun and exciting products and figurines. Choosing the right 3D printer requires much contemplation and consideration. This is why you must keep a few things in mind when selecting a 3D printer that suits your needs.